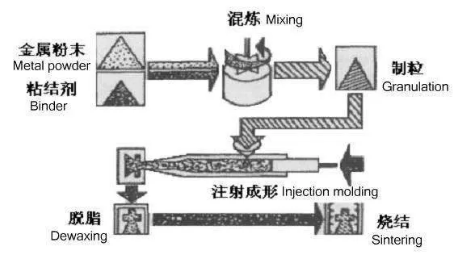

Metal powder injection molding MIM is a molding method in which a plasticized mixture of metal powder and its binder is injected into a mold. It is to first mix the selected powder with the binder, and then granulate the mixture and then inject the required shape. As a near-net-shape technology for manufacturing high-quality precision parts, MIM technology has unmatched advantages over conventional powder metallurgy, machining and precision casting methods.

Equipment required for MIM injection molding: granulating machine, MIM special injection molding machine, degreasing furnace, sintering furnace, testing equipment, secondary processing equipment, etc.

MIM technology is mainly used in consumer electronics, auto parts, medical equipment, hardware tools and other fields. According to statistics from the Powder Metallurgy Branch of China Steel Structure Association, the global MIM market has reached 2.283 billion U.S. dollars in 2016, and the domestic MIM market has increased by In 2012, 1.35 billion increased to nearly 6 billion. The following is a detailed introduction to the specific application of MIM injection molding technology in the field of auto parts.

From the perspective of the application field of auto parts, auto parts are the largest application field of traditional powder metallurgy technology. Based on the advantages of MIM technology, such as excellent performance, low cost, and light weight, it has gradually replaced traditional powder metallurgy technology. It has been obtained on parts with complex shapes such as turbocharged parts, ignition switches, reverse gears, movable roof parts, power steering parts, etc. It is expected to expand the application to more categories in the future.

Finally, the development of China's MIM process technology started late, but the industry has a strong momentum of development. The Pearl River Delta MIM factory is the most concentrated area of the global MIM industry, with nearly 100 processing plants, mainly in Shenzhen, Dongguan, Huizhou and other regions. With the development of the market, the centralization of the competitive landscape is a matter of course. In an environment of rapid market changes and rapid technological breakthroughs, it is particularly important to seize market opportunities.